- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

Nickel Hydrogenation Catalyst SDDZ-6400SI

SDDZ-6400SI Catalyst is a versatile and efficient solution for slurry phase hydrogenation processes. It is particularly well-suited for the hydrogenation of C5 and C9 hydrocarbon fractions, enabling the saturation of multiple unsaturated bonds. Additionally, it demonstrates excellent performance in the hydrogenation of DCPD and PAO. This catalyst helps enhance reaction efficiency, improves product quality, and can be easily integrated into various industrial production setups, making it a reliable choice for a range of chemical reactions involving these substances.

PRODUCT DESCRIPTION

Specifications:

Name | Nickel hydrogenation catalyst |

Other name | C9 hydrogenation catalyst |

Type | SDDZ-6400SI |

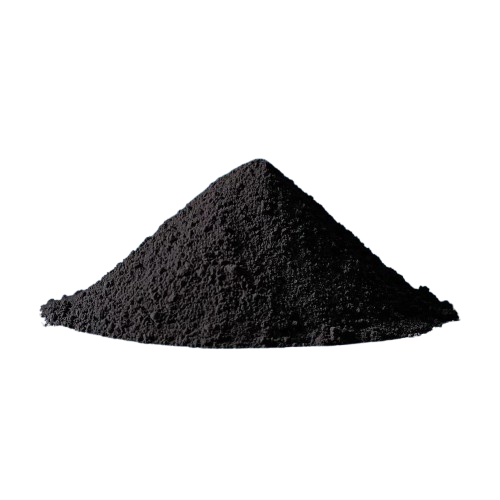

Appearance | Black powder |

Nickel (%) | 55-63 |

Surface area (m2/g) | 120-180 |

Reducibility (%) | ≥65 |

Autoignition temperature (℃) | ≥150 |

Product Features:

It is not prone to catching fire

There is no need for water seal storage. It can be directly exposed to the air without catching fire, which greatly improves the safety during transportation, storage, and use. This can effectively reduce the safety risks for users.

Light in Specific Gravity and Easy to Disperse

It has a relatively small particle size and a light specific gravity. Through stirring, it can be evenly dispersed in the reaction system, which effectively improves the catalytic efficiency.

Good Filtration Performance

The catalyst has a loose structure and a uniform particle size distribution, resulting in excellent filtration effects.

Application Fields:

■ Hydrofining

Solvent de-aromatization, hydrofining of caprolactam, hydrofining of butanol and octanol, hydrofining of higher alcohols, etc. Alcohol (with a small amount of aldehydes, ketones, esters) + H₂ -------> Alcohol (high-quality).

■ Polymer hydrogenation

Hydrogenation decolorization, such as the hydrogenation of petroleum resins, the hydrogenation of polyalphaolefins (PAO), the hydrogenation of oil products, etc.

■ Benzene ring hydrogenation

Hydrogenation of benzene to produce cyclohexane, hydrogenation of aniline to cyclohexylamine, hydrogenation of naphthalene, hydrogenation of bisphenol A, etc.

■ Nitro group hydrogenation

Nitro hydrogenation (m-phenylenediamine, toluene diamine), reductive amination, nitrile hydrogenation, etc.

Related products

Cu Zn Al2O3 Methanol Synthesis Catalyst DZC-98-5

HCLO4 70% perchloric acid 7601 90 3

Perchloric acid 70% HCLO4 7601-90-3

MTO Catalyst (Methanol to Olefins) Catalyst

<< Previous Page

Next Page >>