- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

Catalyst for Methanol Production DZC-98-5

Copper and zinc based methanol synthesis catalysts are widely used in methanol production process. DZC-98-5 Methanol synthesis catalyst is widely applicable to methanol plants with various technologies, including medium and low pressure processes. Properties of the catalyst are greatly enhanced after a remarkable improvement made on its preparation technology. As the result, the catalyst is featured by higher activity, space-time yield and CO conversion. Meanwhile, the catalyst comes with better thermal stability and tolerance to heat, longer service life, better selectivity, higher methanol concentration and less organic by-products in raw product. Also, it has a wide range of operation condition, ease in reduction and operation, higher strength and little pressure drop across the bed.

PRODUCT DESCRIPTION

A highly efficient and stable catalyst designed for methanol production. It has excellent catalytic activity and selectivity and can achieve high methanol yield at low temperatures and pressures.

The reaction is summarized as below:

2H2 + CO → CH3OH

CO2 + 3 H2 → CH3OH + H2O

CO + H2O → CO2 + H2

DZC-98-5 catalyst is based on copper and zinc.

Physical properties:

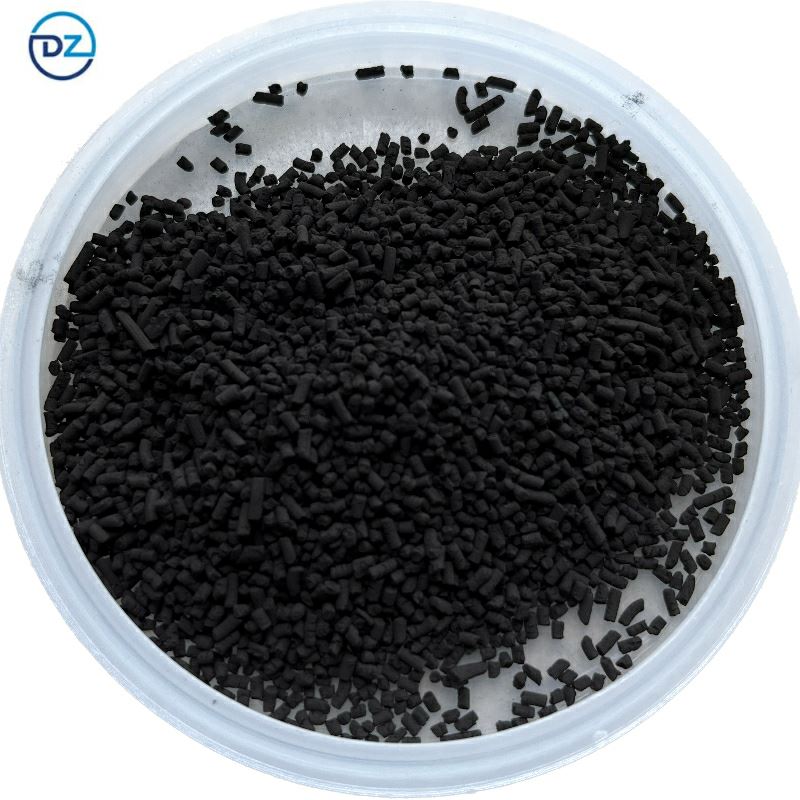

Appearance | Black tablet | Particle size | Φ5×4-5mm |

Bulk density | 1.1-1.4 kg/L | Chemical composition | CuO(>52%) –ZnO(>21%)-Al2O3(>8%) |

Product benefits

① Unique preparation technology ensures excellent high temperature activity, stability and selectivity of methanol synthesis catalyst.

② Using space isolation (Space Isolation) method to improve the activity of the catalyst and enhance the high temperature stability of the catalyst.

③ The use of special methods to form zinc aluminum spinel compounds, effectively preventing and delaying the thermal sintering of copper particles, and enhancing the heat resistance and stability of the catalyst.

④ With the use of special granulation and molding technology, the catalyst has a suitable strength distribution and pore size distribution, improving the overall performance.

Reduction

The catalyst must be activated by reduction before use.

Main reduction reaction:

CuO+H2=Cu+H2O △H°298=-86.6kJ/mol

The reaction is highly exothermal and the bed temperature rise is directly proportional to hydrogen concentration when hydrogen concentration is low, i.e., 1%H2 is equivalent to 28℃. To avoid bed temperature surge caused by violent reaction, which may result in sintering of catalyst and hence loss of activity, low-hydrogen is usually employed. The hydrogen is diluted by inert gases ( e. g., nitrogen, natural gas) to 1-2%. This method is featured by mild reduction condition, reliable operation, ease in control of bed temperature and being favorable to attaining high activity, maintaining the strength and prolonging the service life.

Water formed during reduction accounts for about 20% of the weight of the catalyst, of which 9-12% is chemically resultant and 8~10% physically resultant.

Package and storage

The catalyst is packed in iron barrels lined inside with plastic bags.

It should be stored in dry and well-ventilated place.

The catalyst can usually be stored for several years without remarkable deterioration in its properties.

Related products

Cu Zn Al2O3 Methanol Synthesis Catalyst DZC-98-5

Waste Plastic Oil Catalyst

FCC catalyst

Hopcalite Catalyst DZC-HCT11

<< Previous Page

Next Page >>