- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

Ammonia Synthesis Catalyst DZC-A110

Ammonia synthesis catalyst is used to accelerate the chemical reaction to produce ammonia, a crucial compound used in various industries such as fertilizer, chemical manufacturing and metal processing as well as electronic industry which gets nitrogen from NH3.

The reaction is summarized as below:

N₂+3H₂ ⇌ 2NH₃

PRODUCT DESCRIPTION

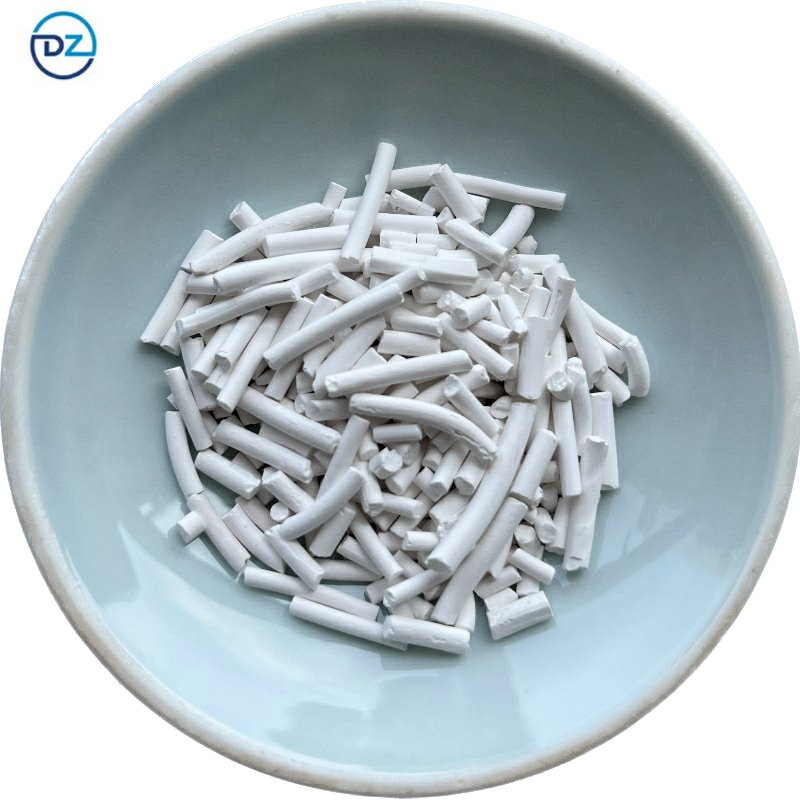

DZC-A110 is an iron-based ammonia synthesis catalyst, and easy to be reduced. It offers high catalytic activity at low temperature, excellent heat resistance and anti-toxicity. Meanwhile, it makes the catalyst more excellent and stable to use high-quality magnetite as raw material. The catalyst can also be used in metallurgy, vacuum tube industry to decompose ammonia into pure nitrogen and hydrogen. The ammonia synthesis catalyst is supplied in its oxidic form (DZC-A110) or as pre-reduced form (DZC-A110-H).

The main components of DZC-A110 are Fe3O4, Al2O3, K2O,and CaO, etc.

Catalyst model | Oxidized (DZC-A110) | Pre-reduced (DZC-A110-H) |

Appearance | Black gray metallically color, Irregular shaped granules | |

Size, mm | 1.5-3.0 | 1.5-3.0 |

Length | 1.5-3.0 | 1.5-3.0 |

Bulk density, kg/l | 2.8-3.2 | 2.3-2.5 |

Total Fe, % | 65-70 | 78-84 |

Content Fe2+/Fe3+ | 0.35-0.45 | 0.42-0.54 |

Content CaO, % | 0.5-1.0 | 0.5-1.0 |

Content K2O, % | 0.5-1.0 | 0.5-1.0 |

Content Al2O3, % | 2.0-3.0 | 2.0-3.0 |

Content SiO2, % | ≤0.4 | ≤0.4 |

Content P, % | 0.04 | 0.04 |

Content S, % | 0.01 | 0.04 |

Content Cо3O4, % | 0 | 0 |

Operating condition

①Operating temperature range of the catalyst is 350-530℃, and it is recommended that the best temperature is 350-500℃. In order to better play the low-temperature activity of the catalyst and extend its service life, the hot- spot temperature should be controlled as low as possible in the early days of the catalyst use, preferably at 470-490 ° C, and the hot -spot temperature can be gradually increased with the use of time.

②The catalyst has a wide operating pressure range. The appropriate operating pressure can be selected in the range of 10-40Mpa according to the requirements of the ammonia synthesis process and equipment.

③Operating space speed range is 6000-30000h-1. Factories can choose the appropriate airspeed according to the process conditions such as equipment, gas purification and operating pressure. Generally, as for the small ammonia converter (no more than φ800mm), 15,000 to 25000h-1 is appropriate. The medium converter is 10000 ~ 20000 h-1, and large converter can be operated at lower airspeeds.

High catalytic efficiency

K2O is an electronic additive, which can improve the specific activity of catalyst. In the processing of the catalyst, K2O and magnetite or other auxiliaries form potassium salt, which is uniformly distributed on the surface of α-Fe after reduction, reducing the electronic work function on the surface of iron, and promoting the desorption and adsorption of ammonia.

Excellent stability and performance

Al2O3 and CaO are structural auxiliaries. During the melting process, solid solution is formed with magnetite, and metal ions enter the tetrahedral and octahedral spaces densely packed with oxygen ions of spinel structure, so that they are evenly distributed in the magnetite. In the process of reduction or use, these oxides are not reduced, which plays the role of isolating α-Fe, making the grains smaller and stable, and improving the activity and stability of the catalyst. In the meanwhile, the anti-toxicity of the catalyst can be enhanced to some extent.

Excellent thermal stability and long service life

A unique additive is added to the catalyst, which can effectively prevent the transfer of potassium ions gathered on the surface of the catalyst to the inner of the catalyst particles, so that potassium ions stay longer on the surface of the catalyst, thus greatly improving the thermal stability and service life of the catalyst.

Storage

①The catalyst is sealed in iron drum and lined with plastic bag, with a net weight of 80Kg per drum. Do not open the lid when not in use to avoid contamination.

②The catalyst should be placed in a dry and ventilated warehouse, and should check the packaging frequently.

③Prevent moisture during storage and transportation, to avoid rolling collision.

Oil, dust and other chemical pollution should be strictly prevented during storage and transportation.

Remarks:

①DZC-A110 ammonia synthesis catalyst is the oxidic form catalyst, which must be reduced with hydrogen before use. Typically, hydrogen nitrogen mixture is used as the reducing gas, on which the Fe3O4 is reduced to α-Fe by hydrogen, and then the catalyst is active.

②DZC-A110-H ammonia synthesis catalyst is the pre-reduced form catalyst with passivation, and the surface of the oxidation film must be destroyed before use.

Related products

Used Tire Pyrolysis Oil Catalyst

FCC catalyst

Synthesis Gas Purification Catalyst DZC-JWH185

Cuo Zno Al2O3 Methanol Steam Reforming Catalyst DZC-Z1

<< Previous Page

Next Page >>