- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

DME (Dimethyl Ether) catalyst

DME (Dimethyl Ether) catalyst, supported by γ-Al₂O₃, is synthesized with the incorporation of a precisely-determined amount of heteropoly acid and promoter. This meticulous formulation significantly elevates its catalytic activity, selectivity, and thermal resistance, rendering it an optimal choice for industrial - scale dimethyl ether production.

PRODUCT DESCRIPTION

Physicochemical Properties

Property | Specification |

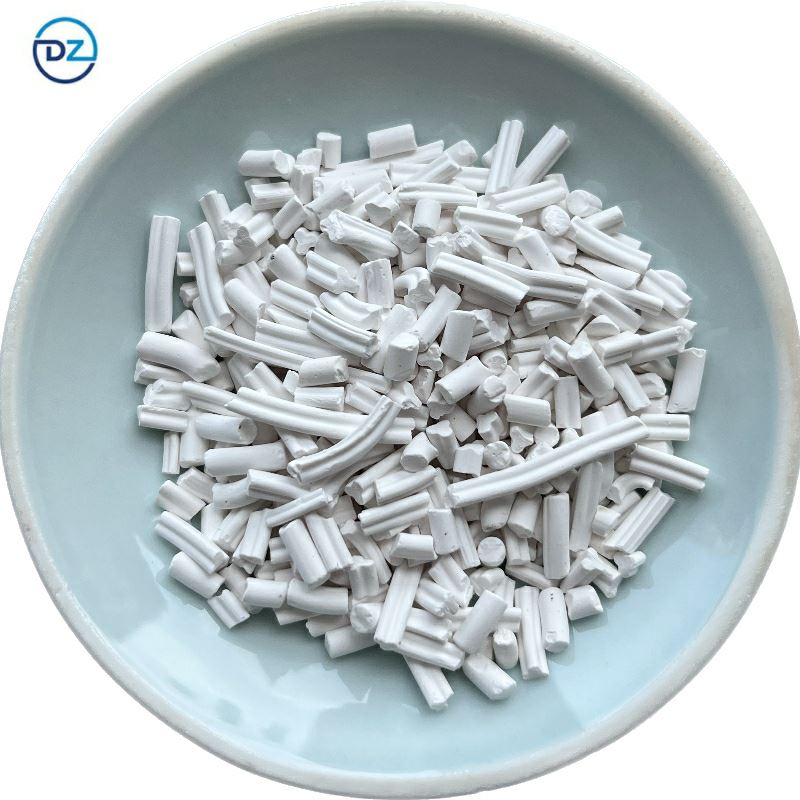

Appearance | White or light yellow extrudates |

Chemical Composition | Predominantly Al₂O₃ |

Dimensions | Diameter: 3 - 4 mm; Length: 3 - 20 mm |

Bulk Density | 0.45-0.50 kg/l |

Specific Surface Area | ≥ 250 m²/g |

Average Radial Crushing Strength | ≥ 80 N/cm |

Abrasion Rate | ≤ 5% |

Performance Indicators

Indicator | Value |

Conversion Rate | ≥ 82% |

Ether Selectivity | ≥ 99.5% |

Process Parameters

Parameter | Range |

Temperature | 240°C - 400°C |

Pressure | 0.1 - 1.2 MPa |

Liquid Hourly Space Velocity (LHSV) | 1 - 2 h⁻¹ |

Application Scope

Specifically engineered for the gas-phase dehydration process to yield dimethyl ether, the DME catalyst demonstrates remarkable versatility. It can effectively utilize both refined and crude feedstocks (derived from synthesis processes without product distillation separation), providing flexibility and cost-effectiveness in the manufacturing process. Extensive industrial applications have affirmed its outstanding performance, characterized by high activity, superior selectivity, low bulk density, broad temperature adaptability, excellent thermal stability, and an extended service life.

Related products

Fluid Catalytic Cracking Catalyst

HDO Catalyst Hydrodeoxygenation Catalyst

Waste automotive engine oil catalyst

Waste Plastic Oil Catalyst

<< Previous Page

Next Page >>