- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

Fischer–Tropsch Process

2024-01-11

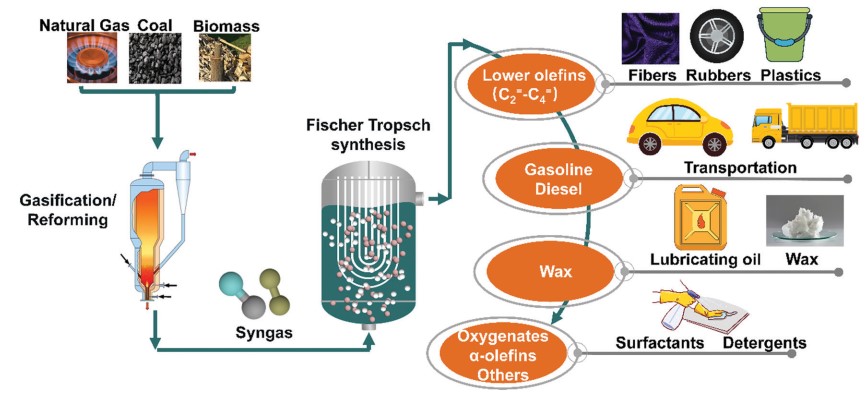

Fischer-Tropsch process, also known as F-T synthesis, is a process in which synthetic gas (a mixture of carbon monoxide and hydrogen) synthesized in liquid form or hydrocarbon (hydrocarbon) under appropriate conditions and catalysts.

This process is a key component of gas liquefaction technology, which typically produces synthetic lubricants with synthetic fuels from coal, natural gas or biomass. Fischer-tropsch synthesis has received intermittent attention as a source of low-sulfur diesel fuel to address the supply or cost of petroleum-based hydrocarbons.

Fischer-Tropsch process includes a series of chemical reactions to produce a variety of hydrocarbons, of which the production of alkanes is more widely used, the reaction equation is as follows, where the alkanes are expressed by the general formula CnH2n+2:

(2n+ 1) H2+nCO → CnH(2n+2)+nH2O

Where N is usually 10-20, methane (N=1) is a useless product. Most of the alkanes produced tend to form straight chains and are suitable for use as diesel fuel. In addition to alkanes, small amounts of alkenes, alcohols and other oxygenated hydrocarbons are produced as by-products.

A variety of catalysts can be used in the Fischer-Tropsch process, most commonly the transition metals cobalt, iron, and ruthenium, and nickel can also be used.

<< Previous Page

Next Page >>