- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

Two Key Catalysts in Industry: Alumina-Supported vs. Zeolite-Based

2025-11-05

Introduction

Catalysts are the unsung heroes behind countless industrial processes, from refining petroleum to producing clean energy. Among them, catalysts supported on alumina and zeolites (like Y-type zeolite) are widely used for their efficiency and versatility. In this article, we’ll explore how these two types work, their unique advantages, and where they are commonly applied.

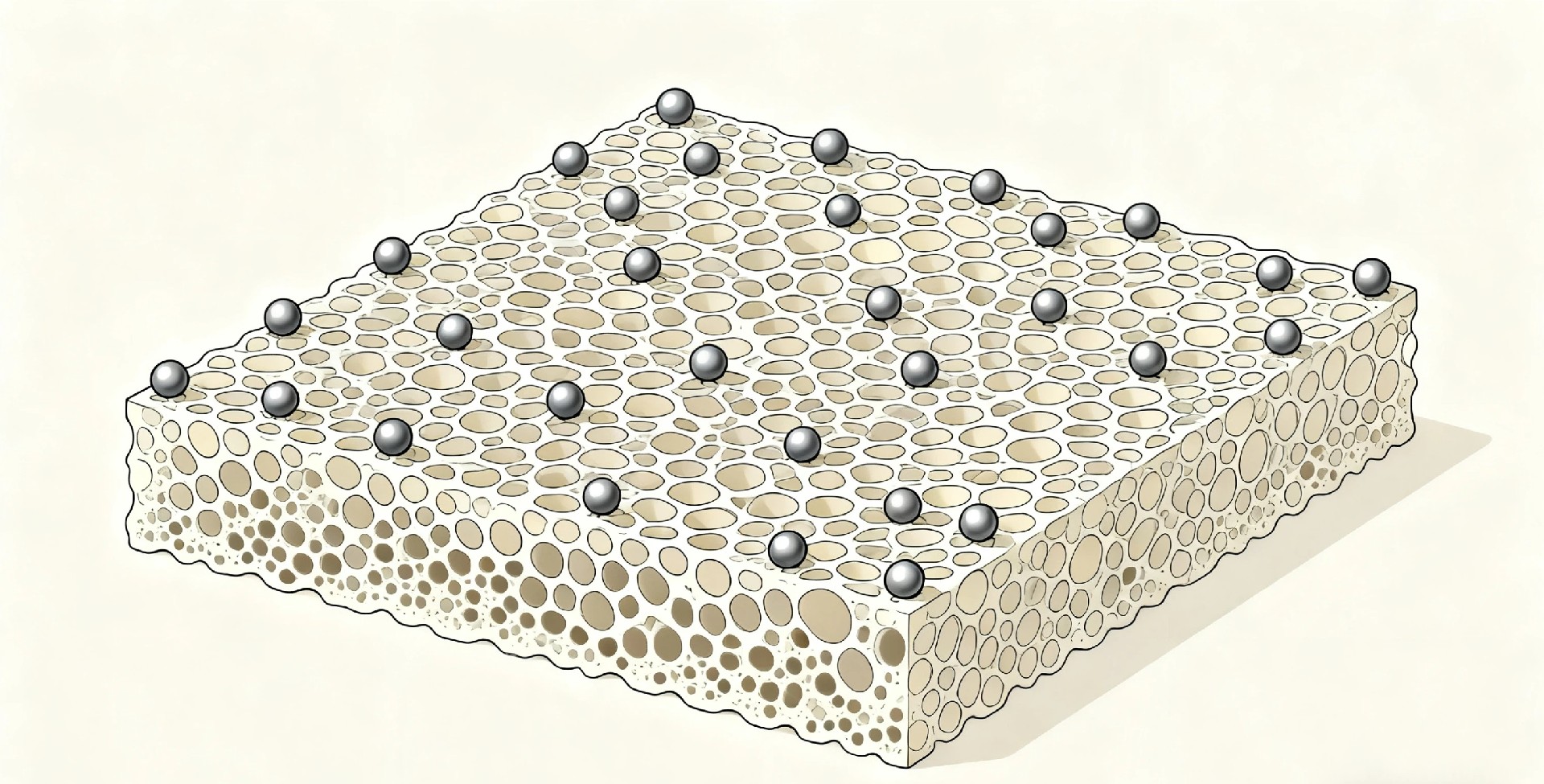

1. Alumina-Supported Metal Catalysts

Alumina (aluminum oxide) is a popular catalyst support due to its excellent physical and chemical properties. It has a high surface area, good thermal stability, and strong mechanical strength, making it ideal for loading active metals like platinum, palladium, or nickel.

Key Features:

High Surface Area: Provides ample space for metal dispersion, enhancing catalytic activity.

Thermal Stability: Withstands high temperatures without degrading, suitable for harsh industrial environments.

Chemical Inertness: Resists reaction with most chemicals, ensuring long-term stability.

Common Applications:

Hydrotreating in refineries to remove sulfur and nitrogen impurities.

Catalytic oxidation in emission control systems.

Hydrogenation reactions in chemical synthesis.

2. Zeolite-Supported Metal Catalysts (e.g., Y-Type Zeolite)

Zeolites are crystalline aluminosilicates with a well-defined porous structure. Y-type zeolite, in particular, is known for its uniform pore size and acidic sites, which can be tailored by adjusting its silicon-to-aluminum ratio.

Key Features:

Shape-Selectivity: The precise pore structure allows only specific molecules to enter and react, enabling highly selective catalysis.

Acidity: Zeolites possess intrinsic acidic sites that facilitate reactions like cracking and isomerization.

Tunable Properties: By incorporating metals (e.g., nickel, cobalt), zeolites can be customized for targeted applications.

Common Applications:

Fluid catalytic cracking (FCC) in petroleum refining.

Isomerization and alkylation in petrochemical production.

Environmental catalysis for NOx reduction.

Alumina vs. Zeolite: A Quick Comparison

While both are exceptional supports, they serve different purposes:

Alumina excels in reactions requiring robustness and broad accessibility, such as hydrotreating.

Zeolites shine in shape-selective and acid-catalyzed processes, like cracking complex hydrocarbons.

Conclusion

Alumina-supported and zeolite-based catalysts are pillars of modern industrial chemistry. Understanding their distinct strengths helps industries optimize processes for efficiency and sustainability. As research advances, these materials will continue to enable cleaner and more efficient technologies.

<< Previous Page

Next Page >>